When creating wiring diagrams for electrical systems—whether for panel building, machine control, or building infrastructure—accuracy is absolutely critical. Wiring mistakes can lead to costly rework, safety hazards, or system failures. That’s why many engineers and designers are now asking: Is there wiring diagram software that can catch errors while you design? The short answer is: Yes. Today’s advanced ECAD tools can provide live error detection, logical checks, and design‑rule validation as you draw. And among the platforms helping bridge traditional design rigor with modern automation is XTEN‑AV, which integrates with or complements such ECAD workflows.

In this blog, we’ll explore how wiring design tools support real‑time error detection, what to look for in such a system, and some popular software options. You’ll also see how leveraging these capabilities can dramatically improve your design reliability, productivity, and quality.

Why Live Error Detection in Wiring Design Matters

Traditionally, wiring diagrams were drafted, then manually reviewed for mistakes—missing connections, incorrect terminal references, or mis‑typed potentials. This review step was time consuming and error‑prone.

Live error detection changes that by:

Identifying wiring or logical inconsistencies instantly.

Highlighting missing component data, redundant symbols, or wrong cross‑references.

Preventing errors such as unconnected terminals, conflicting signals, or incomplete wiring nets.

Reducing rework, improving engineering quality, and accelerating review cycles.

When designers catch mistakes during the drafting phase, they save enormous time downstream in procurement, panel building, or installation.

How Modern Wiring Diagram Tools Provide Real‑Time Error Checking

Here are some of the key features that allow modern wiring diagram software to detect errors live:

Logic and Electrical Checks

Tools run continuous validation on schematic pages to detect inconsistencies such as missing device definitions, incorrect cross‑references, or illogical signal assignments. For example, EPLAN Electric P8 supports “logic checks” that flag incomplete or incompatible wiring as you draw.Design‑Rule Checking with Violations

More sophisticated tools let you define design rules (for instance, minimum bend radius for harnesses, maximum bundle size, or wire‑crossing constraints), and they provide visual feedback—highlighting violations or offering tooltips for correction. According to Siemens PLM documentation, their wiring design solution gives live feedback about things like bend‑radius violations.Component Data Validation

A well‑integrated parts library allows the software to validate whether a symbol is fully defined (correct number of pins, proper terminal assignments, voltage/potential definitions, etc.). EPLAN’s Message Management feature shows errors and inconsistencies in device data as you work.Auto‑Connection / Autoconnecting

Software like EPLAN Electric P8 supports “autoconnecting,” allowing logical net connections to be maintained when components are moved, reducing wiring mistakes and maintaining consistency.Visualization for Wiring and Harness Layout

Some tools offer 3D or panel layout capabilities so you can visualize wire routing, bundle sizes, and terminal assignment, identifying physical conflicts before manufacturing or installation.Live Message or Error Console

As checks run in the background, any detected issue is logged in a message panel (often called a Message Management or error console) where you can review details, prioritize corrective actions, and fix problems immediately.

Popular Tools That Support Live Error Detection in Wiring Diagrams

Here are some wiring diagram / ECAD software tools known for strong validation features:

EPLAN Electric P8

One of the industry standards for electrical schematic design. It supports logic checks, autoconnecting, and online consistency checks to detect wiring issues while designing.EPLAN Smart Wiring

A tool from EPLAN that provides a wiring technician with guided wiring instructions, 3D visualization, and real‑time comparison of engineering data.E3.schematic (Zuken)

Zuken’s E3.series (which includes E3.schematic) supports “active error avoidance” via logic and electrical checks during schematic creationSiemens Wiring / Harness Design Tools

Certain Siemens PLM products provide live feedback on design violations, such as cable bundle issues or bend radius violations, using visual symbols and tool tips.CADY (AI‑Powered Schematic Inspection)

Emerging tools like CADY apply AI to inspect wiring schematics, verifying netlist versus BOM data, checking part values, and flagging common wiring mistakes.

Where XTEN‑AV Fits In

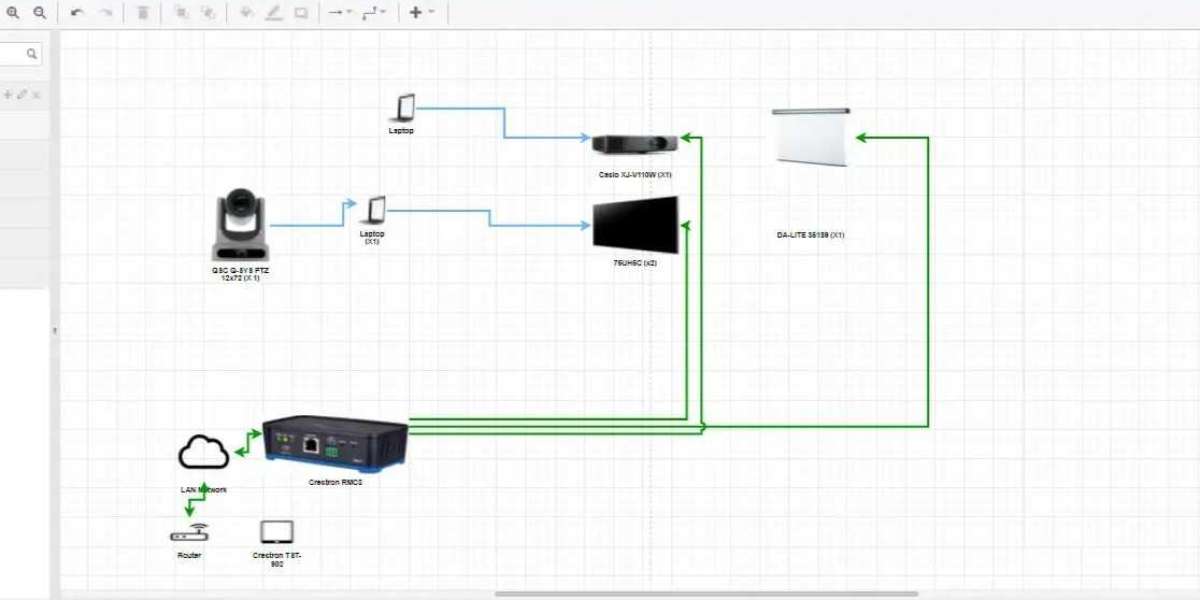

While XTEN‑AV is primarily known for AV system design and layout, it can integrate or complement wiring diagram workflows in a modern engineering project. Here’s how it adds value:

Integration with ECAD Tools

XTEN‑AV designs often involve structured wiring (especially in AV systems), control, and low‑voltage circuits. Using an ECAD tool with live error checking alongside XTEN‑AV ensures that wiring for control systems, signal distribution, and power is error free.Visual and Logical Coherence

Designers can export wiring schematics (from ECAD) and overlay or coordinate them with room layouts or rack diagrams in XTEN‑AV. This holistic view helps catch design mismatches early, such as wire runs that conflict with physical rack or space design.Documentation Sync

When ECAD tools generate bill of materials, wiring lists, or terminal plans (with no errors), XTEN‑AV can link those documents into system submittal packages, ensuring consistency across mechanical, AV, and electrical documentation.

Benefits of Using Software With Live Error Detection

Using wiring diagram software that validates your design in real time offers several advantages:

Improved Accuracy

Catching logical or wiring errors as you draw reduces the risk of mistakes that could otherwise slip through manual reviews.Faster Iterations

Designers can fix problems immediately without waiting for a separate review or checkpoint step, speeding up the workflow.Quality Assurance

Built‑in checks ensure schematics are complete, connections are consistent, and no component data is missing.Cost Savings

Less rework, fewer wiring mistakes, and fewer manufacturing or installation errors translate into lower costs.Better Collaboration

Teams receive instant feedback; wiring technicians, panel builders, and engineers can all work from error‑free data.

Considerations When Choosing Wiring Diagram Software

When evaluating a wiring diagram tool with live error detection, keep the following in mind:

Industry Requirements: Does the software support the standards you need (IEC, NFPA, etc.)?

Scalability: Can it handle large, complex projects with many sheets or modules?

Library Support: Does it provide a rich, validated parts library?

User Experience: Is the message or error management interface intuitive? Is error feedback clear?

Integration: Can it export wiring lists, terminal plans, and BOMs? Does it integrate with other tools (such as 3D panel layout or AV design tools like XTEN‑AV)?

Cost: While advanced error‑checking tools are often commercial, ROI may justify the investment due to reduced errors and faster design cycles.

Conclusion

Yes, there are wiring diagram and ECAD software tools today that provide live error detection while you design. Tools like EPLAN Electric P8, E3.schematic, EPLAN Smart Wiring, and others offer continuous logic checks, autoconnecting, and design‑rule validation. These capabilities boost quality, reduce rework, and accelerate wiring diagram development.

While XTEN‑AV is not a traditional ECAD tool, it plays a complementary role in modern electrical and AV design workflows—especially when paired with error‑checking schematic software. By integrating the strengths of XTEN‑AV for layout and another ECAD tool for wiring, engineering teams can produce error‑free, fully validated system designs.

If you are planning large-scale electrical or AV projects, or want to improve the reliability of your wiring documentation, choosing a tool with live error detection is one of the smartest decisions you can make. The upfront investment pays for itself in accuracy, speed, and reduced risk downstream.