An impregnated core bit is a type of diamond drill bit where synthetic or natural diamonds are uniformly distributed throughout a metal matrix, typically composed of tungsten carbide or other hard materials. This design ensures continuous cutting action as the matrix wears down, exposing fresh, sharp diamonds to maintain performance over time.

HQ refers to a standard core size in the wireline coring system defined by the Diamond Core Drilling Series (DCDMA) standards. It is designed to cut hard and abrasive rock formations efficiently and produce an HQ-size rock core (63.5 mm diameter). Typical dimensions for HQ Impregnated Bits are Hole diameter: 96 mm; Core diameter: 63.5 mm; Core barrel outer diameter: 77.8 mm. Other common sizes of impregnated Core bits are BQ (36.4 mm core), NQ (47.6 mm core), and PQ (85 mm core).

The feature of HQ Impregnated Core Bits

· Suitable Formations

HQ impregnated bits are designed for medium-hard to very hard, consolidated formations: rocks such as granite, quartzite, basalt, and gneiss. The fine synthetic diamonds are evenly distributed in a metallic matrix, providing continuous exposure of sharp cutting edges as the matrix wears. This makes HQ bits ideal for formations that are too hard or abrasive for surface-set bits. 【1】

· Waterway Design (Flushing System)

The number and shape of waterways in an HQ bit are determined by the expected rock hardness, abrasiveness, and drilling fluid volume.

- Hard and abrasive formations require more and deeper waterways to ensure smooth removal of cuttings and efficient cooling.

- Softer, less abrasive formations may use fewer, narrower waterways to maintain matrix strength and bit stability.

- Waterway shapes vary:face-discharge, twin-flushing, or deep-solt types, to balance fluid velocity and diamond exposure. 【1】

· Crown Height

The crown height—the impregnated section of the bit—typically ranges from 9 mm to 16 mm depending on drilling depth and formation type.

- Higher crowns (e.g., 16 mm) extend bit life in deep or abrasive holes but need greater rig power and stable flushing.

- Lower crowns (e.g., 9 mm–12 mm) are used for shorter holes or softer formations to allow faster matrix renewal.

· HQ vs Other Sizes (NQ / PQ Comparison)

- NQ (47.6 mm core) – lighter load, smaller rig, faster in narrow boreholes.

- HQ (63.5 mm core) – balance between torque, core volume, and hole stability.

- PQ (85 mm core) – larger sample, but heavier torque and slower in ultra-hard rock.

Comparison of Impregnated Core Bit Sizes (NQ / HQ / PQ)

Size | Hole Diameter (mm) | Core Diameter (mm) | Rod Outer Diameter (mm) | Main Features | Typical Application |

NQ | 75.7 | 47.6 | 69.9 | Lighter load, suitable for smaller rigs; faster penetration in narrow or medium-depth holes. | Medium-hard formations where mobility and drilling speed are priorities. |

HQ | 96.0 | 63.5 | 88.9 | Balanced torque and rigidity; good core recovery and gauge stability in hard to very hard formations. | Standard size for hard or abrasive formations; ideal for mineral exploration and geotechnical coring. |

PQ | 122.6 | 85.0 | 114.3 | Produces large-diameter cores; requires high torque and slower rotation; best for deep or structural holes. | Deep or large-diameter drilling projects needing high-quality core samples. |

Why choose ROCKCODE

The effectiveness of impregnated core bits stems from meticulous design focused on optimizing the interaction between the bit and the rock formation. This design steadily maintains a small contact area between the diamond bit work face and the rock formation during drilling to increase the unit load acting on the single diamond and improve the ROP. 【2】

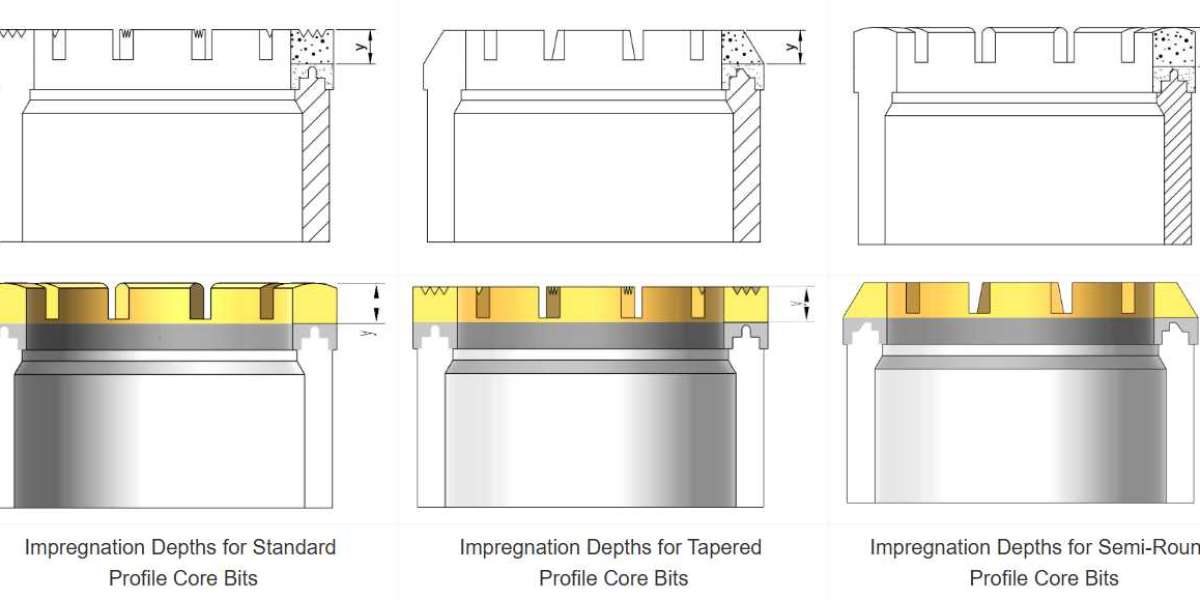

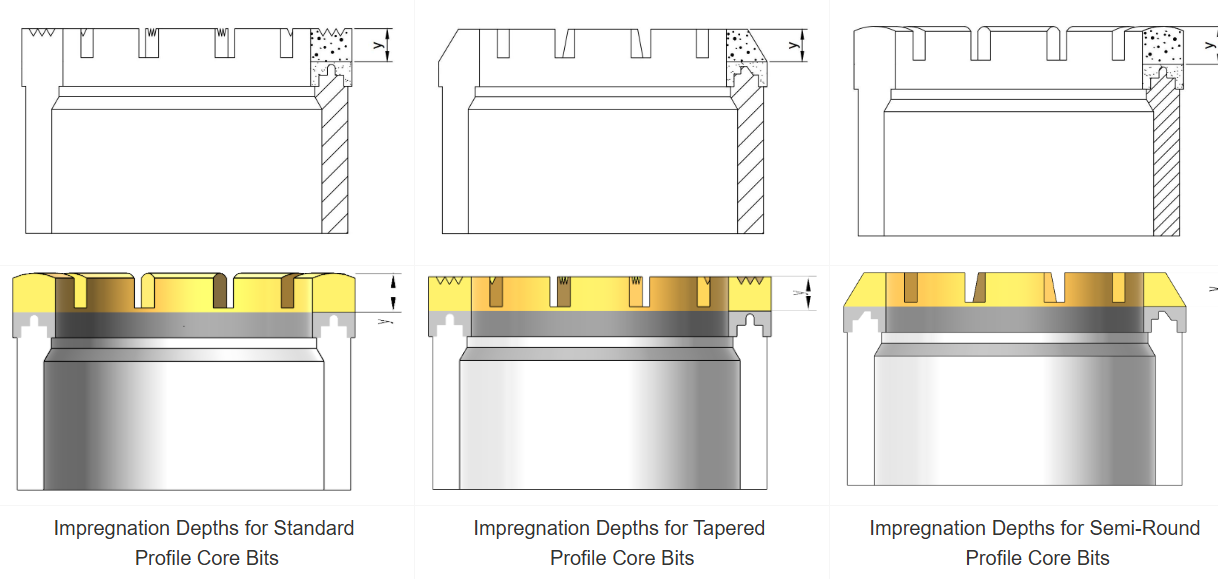

ROCKCODE offers comprehensive customization options to match specific drilling requirements. Our standard impregnation depths range from 9 mm to 20 mm, with the flexibility to manufacture custom depths based on project specifications. For most applications, we supply a standard 12mm impregnation depth that has proven optimal for balancing durability and cutting efficiency across various formation types.

ROCKCODE HQ Impregnated Core Bits Highlights

ROCKCODE can manufacture high-quality HQ impregnated core bits with elongated face discharge. This kind of HQ impregnated core bits is suitable for broken sedimentary or metamorphic formations, and the elongated hole is more efficient than the round hole.

HQ IMP (Spherical) Y=16mm 8WW Elongated Face Discharge

Normally, a new impregnated diamond bit requires a short “bit opening” period to expose the first layer of diamonds before reaching full drilling performance. However, this raised pad design (see picture below) allows the bit to contact the rock immediately with concentrated pressure, which helps the diamonds become active faster. Therefore, no pre-conditioning or bit-opening run is required, saving time and reducing wear on the drilling system.

HQ IMP BIT10WW Y=12mm WATERWAY SETTING

Front: NQ IMP BIT8WW Y=12

Back: HQ IMP BIT10WW Y=12mm

→ For more information about ROCKCODE’s HQ impregnated core bits, please visit: https://www.rockcodebit.com/impregnated-diamond-core-bit.html

→ Email us at: [email protected]

→ Information in this article is for general reference only. For specific drilling projects and drilling bits, please consult qualified professionals. Thank you.

Source

1. https://www.asahi-diamond.com.au/documents/datasheets/Parameters_for_the_use_of_Drill_Bits.pdf

2. https://www.sciencedirect.com/science/article/abs/pii/S0263436813002321?via%3Dihub

https://www.rockcodebit.com/guide-to-hq-impregnated-core-bits.html