In modern IT, AV, and data centre environments, efficient space planning is a must. Whether you are designing a small server room or a large-scale network infrastructure, proper rack organization determines not just how neatly your equipment fits, but also how well your system performs. One of the most important aspects of rack design is understanding and selecting the correct rack unit, commonly known as RU or U, for your equipment.

This is where rack diagram software comes in. By providing precise visualization, equipment libraries, and automated dimensioning, rack design tools make the process of selecting and arranging rack units far easier and more efficient. In this blog, we will explore how rack design software helps you determine the right RU sizes, optimize space, and avoid costly installation mistakes.

What Is a Rack Unit (RU or U)?

Before we dive into the role of design tools, it’s important to understand what a rack unit is. A rack unit (RU or simply U) is a standard measurement used to describe the height of electronic equipment intended for mounting in a rack frame. One rack unit equals 1.75 inches (44.45 mm) in height.

Rack-mounted equipment—such as servers, switches, amplifiers, and power distribution units—is typically designed in increments of rack units. For instance:

A 1U device is 1.75 inches tall.

A 2U device is 3.5 inches tall.

A 4U device is 7 inches tall.

Most standard server racks are 42U or 45U tall, which means they can accommodate 42 or 45 rack units of equipment. Understanding these measurements ensures efficient use of space, proper airflow, and easy access for maintenance.

The Challenge of Rack Unit Selection

Without the right tools, planning rack unit sizes can quickly become complex. When managing dozens of devices, ensuring they fit neatly and function efficiently requires careful calculation.

Common challenges include:

Misjudging space requirements for larger equipment.

Overcrowding racks and blocking airflow.

Leaving too much unused rack space.

Failing to plan for cable routing or future expansion.

Manual methods such as spreadsheets or hand-drawn diagrams often lead to errors. That’s why professionals now rely on advanced rack diagram software to accurately visualize equipment placement and calculate rack unit usage.

How Rack Diagram Software Simplifies Rack Unit Planning

Modern rack design software does more than just draw boxes. It provides intelligent features that automatically calculate, visualize, and optimize rack usage. Let’s look at how these tools help with selecting the right RU sizes for your equipment.

1. Automatic Dimension Recognition

Most professional rack diagram software includes a comprehensive equipment library. Each component comes with predefined physical dimensions, including height in rack units (U), width, and depth. When you drag and drop a device into your rack layout, the software automatically assigns the correct RU value. This eliminates manual measurement errors and ensures accuracy.

2. Real-Time Rack Space Visualization

As you add devices to your virtual rack, the software visually updates the available space. You can instantly see how many rack units are occupied and how many remain free. This real-time feedback helps you plan efficiently and prevents overfilling or underutilizing your rack.

3. Compatibility and Fit Checks

The software checks whether each device fits within the physical constraints of the selected rack model. For example, if a rack is 42U but your design exceeds that capacity, the software will flag it. Some advanced tools even alert you about weight or airflow considerations.

4. Support for Multiple Rack Configurations

If your project involves multiple racks, you can easily compare how different layouts affect rack space utilization. The software enables quick adjustments and ensures balanced distribution of equipment across racks.

5. Customization of Rack Units

While standard racks use 1.75-inch units, some equipment may have non-standard sizes or require extra space for cooling or cabling. Rack design software allows you to customize rack unit allocations, reserve empty slots, or add filler panels as needed.

Optimizing Rack Space Beyond Just Fit

Rack planning isn’t just about making things fit—it’s about creating a design that promotes efficiency and scalability.

Here’s how rack diagram software helps beyond simple rack unit measurement.

1. Thermal Management

By accurately modeling your rack layout, the software helps identify potential hotspots. You can leave intentional gaps between high-heat devices or plan airflow management using blanking panels.

2. Cable Routing and Power Planning

Many design tools allow you to visualize cable paths and power connections within each rack. This ensures that power supplies, network switches, and other devices align logically, minimizing clutter and improving serviceability.

3. Future Expansion Planning

As businesses grow, so do their equipment needs. With digital rack diagrams, you can plan for future additions by leaving dedicated rack units empty or marking placeholders for upcoming installations.

4. Equipment Grouping

You can group equipment by function or department—such as separating network gear from audio processing units or storage servers. This not only improves organization but also simplifies troubleshooting.

Example: How a Typical Rack Design Workflow Looks

Create a new project: Start by defining your rack height, width, and depth.

Select components from the library: Choose devices like servers, routers, amplifiers, or patch panels. Each comes with its predefined RU dimension.

Place devices in the rack: Drag and drop equipment into the virtual rack view. The software automatically adjusts spacing and displays total used RUs.

Check for space and compatibility: The system alerts you if you exceed rack capacity or if certain equipment does not fit.

Export or document your design: Generate detailed rack diagrams, bill of materials, and equipment lists for procurement or installation.

By following this digital workflow, engineers can easily ensure every device fits perfectly—saving time, avoiding manual errors, and improving accuracy.

XTEN-AV and Rack Planning Automation

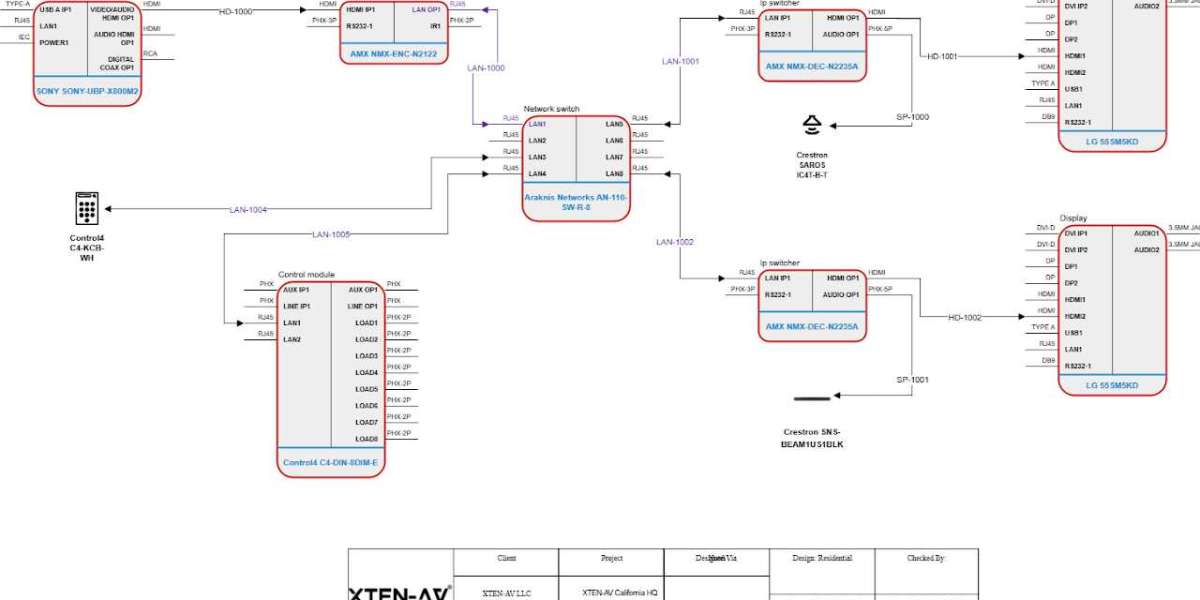

XTEN-AV’s advanced design automation platform shows how modern software can transform rack design and system documentation. Built for AV and IT professionals, XTEN-AV simplifies complex design tasks using intelligent automation, cloud collaboration, and powerful visualization.

Its platform functions as more than just a drawing tool—it acts as an intelligent design assistant. You can easily map out racks, assign RU sizes, and even automate documentation. For teams managing multiple installations or data centres, XTEN-AV brings clarity and speed to every stage of the process.

With features inspired by cutting-edge rack diagram software, XTEN-AV represents the evolution of design tools that merge technical accuracy with workflow efficiency.

Benefits of Using Rack Diagram Software for RU Selection

Accuracy: Automatically calculates rack unit sizes for all devices.

Speed: Reduces manual layout and measurement time.

Visualization: Provides a clear, real-time view of your rack configuration.

Scalability: Supports multiple racks and expansion planning.

Documentation: Generates reports, diagrams, and inventory lists.

Error Reduction: Prevents overcrowding or misplacement of equipment.

Best Practices for Rack Unit Planning

Always leave a few extra RUs for airflow and future upgrades.

Place high-heat devices near cooling zones or at the top.

Keep heavy equipment near the bottom for stability.

Maintain consistent labeling and documentation.

Review and update your rack diagrams whenever hardware changes.

Conclusion

Yes, rack diagram software absolutely helps you choose the right rack unit sizes for your equipment. It takes the guesswork out of planning by providing accurate dimensions, real-time visualization, and intelligent design assistance.

By adopting professional rack design software, you gain greater control, improved accuracy, and better long-term management of your physical infrastructure. For organizations that prioritize precision and efficiency, tools like XTEN-AV set the standard for smart, modern rack planning.

With automation, collaboration, and clarity at its core, XTEN-AV proves that designing your racks the right way—down to the last rack unit—doesn’t have to be complicated. It just has to be smart.

Read more: https://myliveroom.com/blogs/25610/Are-cloud-based-rack-diagram-and-rack-design-tools-safe